Unveiling the Secrets of CCR Oxygen Sensors – Lifespan, Maintenance, and Safety Insights for Technical Divers!

In the world of closed-circuit rebreathers (CCR), the proper functioning of oxygen sensors plays a critical role in ensuring diver safety and optimal gas management. These sensors are vital components that monitor the oxygen levels within the rebreather loop. Understanding oxygen sensors’ lifespan and maintenance requirements is crucial for CCR and technical divers. In this article, we will explore the technical aspects of oxygen sensors and their lifespan, factors affecting longevity, maintenance practices, and signs of sensor degradation.

Description of the oxygen sensors

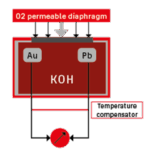

The oxygen sensors in a rebreather consist of a sensing electrode, a reference electrode, and an electrolyte. When exposed to oxygen, a chemical reaction occurs within the sensor, generating an electric current proportional to the oxygen concentration. This current is then interpreted by the CCR’s control system to regulate oxygen flow into the loop, ensuring optimal gas mixtures for the diver’s safety and comfort during the dive.

The Role of Oxygen Sensors in CCR Rebreathers

Closed-circuit rebreathers operate on the principle of recycling exhaled gases, allowing divers to extend their bottom times while minimizing gas consumption. Oxygen sensors are an integral part of the rebreather system, responsible for continuously monitoring the oxygen content in the breathing loop. These sensors provide real-time feedback on the PpO2 to the rebreather’s controller, enabling the solenoid or the CCR diver to adjust the oxygen flow and maintain the desired setpoint.

Lifespan of Oxygen Sensors in CCR Diving

The lifespan of oxygen sensors in CCR rebreathers can vary depending on several factors. Typically, these sensors have a recommended operational lifespan of 12 to 18 months, but individual sensor performance can differ. Some oxygen sensors may last longer, while others may require replacement sooner. The duration depends on the sensor’s manufacturer, model, usage patterns, environmental conditions, and maintenance practices.

Factors Affecting Sensor Longevity

- Exposure to High Oxygen Levels: Oxygen sensors are designed to operate within a specific oxygen partial pressure range. Exposure to higher oxygen levels than recommended can accelerate sensor degradation. The most common circumstance is setting up the rebreather a day or two before diving and leaving 100% oxygen in the loop after calibrating the sensors until the unit is used. This means the sensors were exposed to very high oxygen levels for a long period before use, which can shorten the sensors’ life quite a bit.

- Best practice: if your rebreather loop has an elevated PO2 and will not be used for a while, then flush the loop with diluent to keep the loop PO2 to a minimum.

- Temperature: Extreme temperatures can impact the sensor’s response time and accuracy. Operating within the recommended temperature and humidity range helps maintain sensor longevity. Heat has a major impact on oxygen sensors’ life; it can be significantly shortened by excessive exposure to heat. Sensors should never freeze, for example, while left in a car overnight.

- Humidity: Humidity in the air can affect accuracy, although generally, the error is small, particularly compared to errors introduced by bad design or user technique. Water in the sensor instrument can render the instrument inaccurate and cause irreparable damage. Even if the seawater does not cause corrosion, it may dry, leaving a deposit on connectors and sensor membranes.

- Mechanical Stress: Physical damage to the sensor’s protective membrane or internal components can lead to premature failure. Proper handling, avoiding physical shock, and protection are essential to prevent mechanical stress on the sensor.

Maintenance and Replacement

Regular maintenance and periodic sensor replacement are essential to ensure accurate readings and reliable performance. Here are some key practices:

- Calibration and Testing: Regularly calibrating and testing oxygen sensors using certified gas mixtures helps verify their accuracy and reliability.

- Visual Inspection: Conduct visual inspections to check for any physical damage, such as cracks, corrosion, or loose connections. Replace sensors that show signs of damage.

- Routine Replacement: Follow the manufacturer’s guidelines for sensor replacement intervals. Proactive replacement before reaching the end of the recommended lifespan is advisable to minimize the risk of sensor failure during a dive.

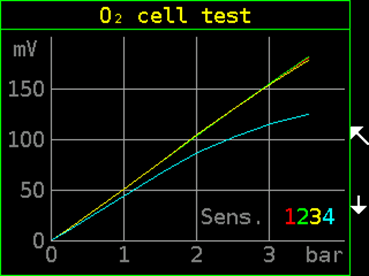

- Testing: The sensor tester from Divesoft converts the Liberty head into a sensor checker. It enables testing the linearity of the sensors up to 3.5 bars with pure oxygen, therefore detecting any non-linearity above 1 bar PpO2.

Signs of Oxygen Sensor Degradation

Divers and technicians should be aware of potential signs indicating oxygen sensor degradation. These may include slow response times, erratic readings, failure to stabilize at a setpoint, or consistently reading a lower or higher oxygen concentration than expected. If any of these signs occur, it is crucial to investigate and replace the sensor if necessary.

Shelf life of a new, unopened CCR Oxygen sensor?

The manufacturers specify the shelf life for most types of sensors at 12 or 24 months from the date of manufacture, and that’s reasonable for sensors intended for use in analyzers. However, you should use a fresher sensor in rebreather applications. For this reason, we can question the need to keep a ‘backup’ sensor in the spare kit. Rotating a sensor from the spares kit into the rebreather might seem cost-effective, but not the best practice. There are various reasons, but ultimately rattling around in the spares kit is hard on sensors, and they often come out of the bag not working well anyway.

If you feel you need to keep a spare sensor for immediate availability, such as during dive travel, that’s great. They are sometimes available overnight if you suddenly need a replacement sensor. In that case, it should be discarded 18 months after the date of manufacture, regardless of whether it was used or not.

Safeguarding Adventures: The Vital Role of Oxygen Sensors in CCR Rebreathers

Oxygen sensors are essential components in CCR rebreathers, ensuring accurate oxygen monitoring and maintaining diver safety. Understanding the lifespan and factors affecting the longevity of these sensors, along with good practices, is crucial for divers and technicians to ensure reliable performance and enhance the overall diving experience.

Choosing to use a sensor for an additional six months beyond recommendations might save

a few dollars but expose you to an unknown but very significant risk.